Products

Number of views:

1001

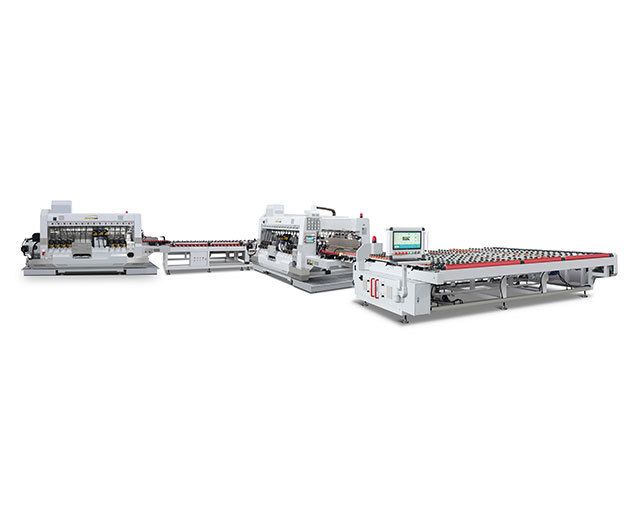

BYS10024-DN

Jumbo Size (10 meter) Full Automatic High-speed Double Edger (24-26 Spindles)

- Product Description

-

Product Features Introduction

1. Specially designed to process extra large size glass (max to 10 * 3.3 meter), and also able to process small size glass (min to 1000*450mm).2. Installed with intelligent control system with low requests to workers or operators, and no need to adjust wheels (spindles) manually during process.

3. Specially designed grinding and polishing motors, with excellent structures and scientific placement method to get high processing speed, high efficiency and stable grinding quality.

4. All grinding motors controlled by inverters to work at about 4200 rpm to decrease energy consumption, reduce grinding marks and increase grinding & polishing effect.5. Automatic support bars to be equally placed in middle position to prevent deformation of large size glass and ensure polishing effect.

6. Equipped with oversize detect device to monitor glass size, if actual glass size exceeds the limit, the system will decelerate, or stop to alarm to prevent breaking glass or burnt motors.

7. Main transfer driven by bi-servo motors to ensure the synchronism, with high polishing effect and easy maintenance.

8. 24 - 26 wheels (spindles) optional.

9. Film Deletion or Servo Corner Cut (Corner Dubbing) functions optional.

Key words:

BYS10024-DN

Related Products

BYS4525-A (28 grinding heads)

Fully Intelligent High-Speed Double Straight-Edge Machine Production Line (L-shaped)

BYS4525-A (26 grinding heads)

Fully Intelligent High-Speed Double Straight-Edge Machine Production Line (L-shaped)