Products

Number of views:

1001

BYS2525-A (14 grinding heads)

Fully intelligent high-speed double straight-edge machine production line (straight line)

- Product Description

-

Product Feature Introduction

1.Uses an intelligent detection table to detect the size of the glass, achieving automatic adjustment of any size without manual input, greatly improving the processing capacity of individual orders.

2.Using a combination of servo drive and high-precision ball screw structure, the opening and closing speed can reach 10m/min, and the opening and closing repeat positioning accuracy is +0.02mm.

3.Glass [4, 5, 6, 8 li] grinding amount 3 mm, rough grinding, polishing speed can reach 20 meters/minute, the production capacity is 5 times that of ordinary double-sided machines;

4.Single-sided 7 grinding head configuration: The diamond wheel, resin wheel, and polishing wheel all use servo automatic feed, automatic compensation after wheel wear, and automatic alarm and wheel replacement function after the wheel is completely worn. No manual adjustment is required, ensuring better edge grinding quality.

5.Double-sided machine remaining amount identification function: Also known as the secondary detection function, it is used to detect in real time when the actual remaining amount of the glass exceeds the set range (the glass size is too large or the cut surface has a bevel). The equipped automatic secondary detection will monitor in real time. If the glass exceeds the grinding position, it will automatically decelerate according to the remaining amount to ensure the safety of glass grinding.

6.Truly solves the problem of fast grinding and chipping: Through the high-speed motor and grinding head grinding method (angle) principle to reasonably distribute the grinding wheel placement position, to change the grinding speed and chipping problem. [Truly bid farewell to the traditional high-speed grinding machine slow grinding speed and chipping problems].

7.Jinbo high-speed grinding head motor, the huge change in motor structure lies in better rigidity, changing the problem of insufficient grinding force.

8.Lower synchronous belt conveyor track: It is an independently developed invention. The difference from its peers is the structure and the use of 304 stainless steel material, high installation accuracy, greatly increasing wear resistance, extending the service life of the synchronous belt and guide rail, etc., which is 10 times the normal service life of peers, and bids farewell to the disadvantages of frequent replacement and poor wear resistance of traditional grinding machines.

9.Suitable for processing rough grinding of construction, rock slabs, rough grinding of doors and windows, hollow, home appliance glass, etc.

10.Can be connected with upper and lower plate tables and cleaning machines to realize unmanned automatic production lines, greatly reducing costs.

- Dual Servo Drive

- Bottom Edge Polishing Manual and Automatic Structure

- Top Chamfering Manual and Automatic Structure

- Rough Grinding Bottom Edge Manual and Automatic Structure

- Beveling Manual and Automatic Structure

- Film Removal Function (LOW-EGlass)

Main Technical Parameters

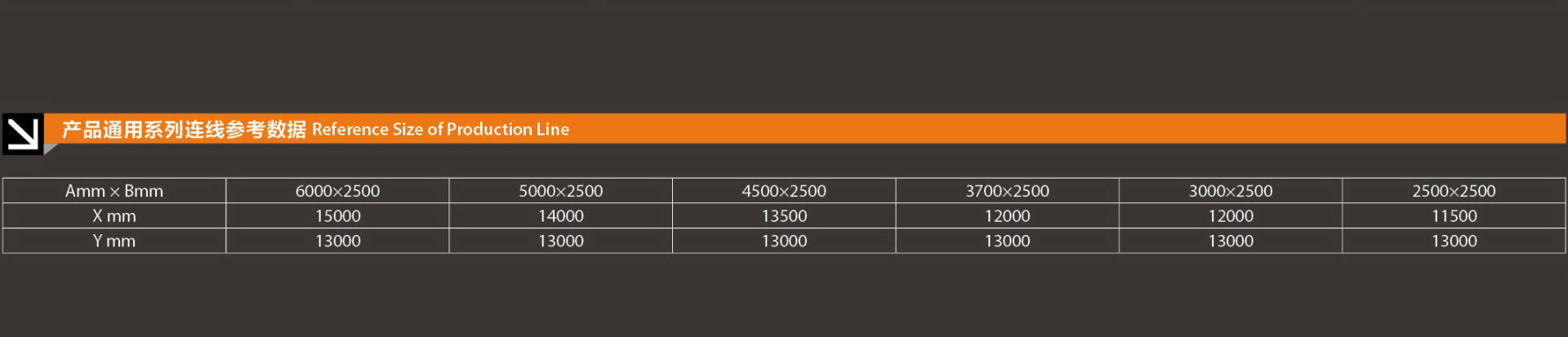

Product General Series Connection Reference Data

Key words:

BYS2525-A (14 grinding heads)

Related Products

BYS4525-A (28 grinding heads)

Fully Intelligent High-Speed Double Straight-Edge Machine Production Line (L-shaped)

BYS4525-A (26 grinding heads)

Fully Intelligent High-Speed Double Straight-Edge Machine Production Line (L-shaped)