Products

Number of views:

1001

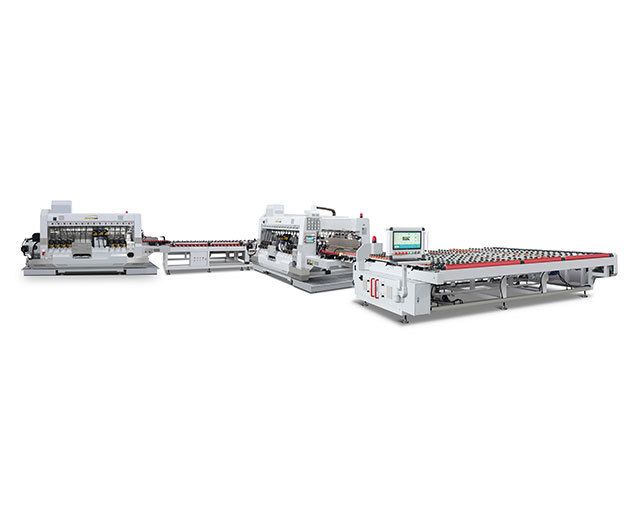

BYS4525-A (24 grinding heads)

AI High-Speed Double Straight Edge Machine Production Line (L-shaped)

- Product Description

-

Product Feature Introduction

Performance Overview of AI High-Speed Double-Sided Edging Machine: The AI high-speed double-sided edging machine is a type of double-sided linear edging machine (26/24/22 grinding heads) developed by our company based on years of experience in edging machine manufacturing. It is mainly suitable for high-end furniture, fish tanks, and architectural glass series. It is primarily used for architectural glass, appliance glass, and insulating glass for doors and windows that require fast processing speeds. Its processing specifications are complex. This production line can use an automatic detection system to detect the glass Size, enabling automatic adjustment of any Size without manual input, greatly improving the processing efficiency of individual orders and achieving unmanned automated production, replacing the various uncertainties of manual operation. It can also optionally use an automatic barcode scanning function. At the input end of the detection table, it can detect the glass barcode Size for intelligent adjustment, enabling fast Size detection and adjustment. This process reduces manual operation and input errors. A margin detection system is added to the feeding point of the double-sided machine's moving side to detect changes in the Size of the incoming glass in real time. Once the system detects an oversized Size, it immediately reduces the conveying speed accordingly. This avoids overloading or even glass breakage that can occur in traditional glass edging when the glass Size margin exceeds the limit, avoiding the various uncertainties of glass opening and leaving margins, greatly improving efficiency and quality and reducing labor costs. The development of Guangdong Jinbo's intelligent automated production line fills a domestic gap, supporting the localization of fully automated and highly intelligent cold-processed glass automated production lines, and serving as an engineering demonstration for the transformation and upgrading of traditional industries using intelligent equipment and an engineering demonstration of intelligent manufacturing.

Description

Suitable for processing glass in industries such as flat architectural glass, shower room glass, furniture glass, and appliance glass.

The bed base uses a linear double guide rail and high-speed screw drive, and the motor automatically opens and closes to detect glass Specification. The opening and closing speed is up to 10 meters/minute. This improves the efficiency and speed of processing individual orders.

The machine's no-load speed reaches 1-20 meters/minute. The edging speed reaches 0-20 meters/minute. Others technical parameters and features are the same as conventional double-sided machines, ensuring its quality stability and safety.

It can be used in conjunction with upper and lower plate tables, saving labor and increasing production efficiency.

Main Technical Parameters

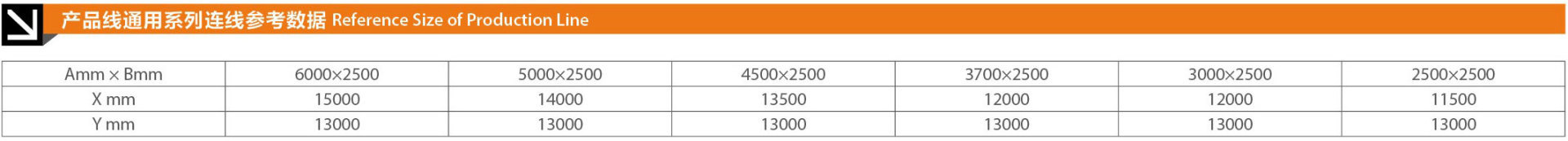

Product Line General Series Connection Reference Data

Key words:

BYS4525-A (24 grinding heads)

Related Products

BYS4525-A (28 grinding heads)

Fully Intelligent High-Speed Double Straight-Edge Machine Production Line (L-shaped)

BYS4525-A (26 grinding heads)

Fully Intelligent High-Speed Double Straight-Edge Machine Production Line (L-shaped)